Executive Summary (TL;DR)

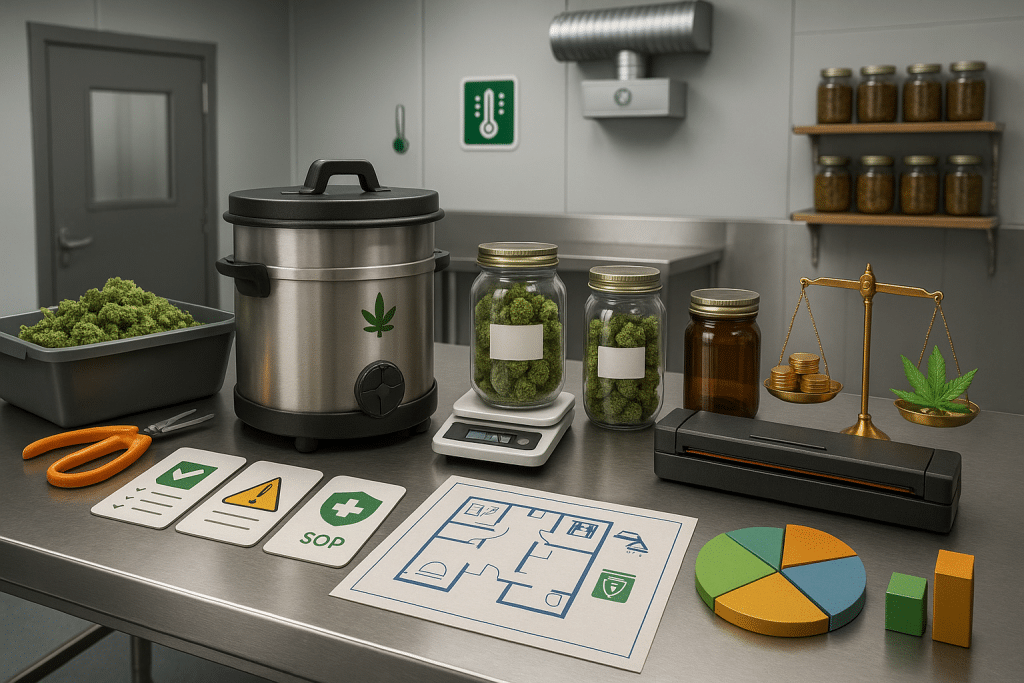

- Trimming and processing turn harvested biomass into sellable SKUs; the winners combine disciplined SOPs, compliant facilities, and precise moisture/handling controls.

- Real estate selection drives speed to license: confirm zoning, buffers, odor control, utilities, and CUP/building permit pathways before you underwrite.

- Choose hand vs. machine trim based on your brand promise, throughput targets, and labor profile; model cost per finished pound and revisit quarterly.

- Build a compliant QA system (cGMP/HACCP) with batch records, hold‑and‑release, and sanitation; align with your state track‑and‑trace.

- Operators and investors can de‑risk execution by aligning site design, workflow, and equipment to the exact SKUs and volumes you plan to sell.

In-market operators and investors can find cannabis real estate and businesses for sale on 420 Property to evaluate compliant facilities and expansion options.

Table of Contents

- What “trimming and processing” include (and what they don’t)

- Cannabis trimming and processing fundamentals

- Real estate, zoning, buffers, and permitting

- Licensing path and compliance artifacts

- Process flow & SOPs from harvest to packaged flower

- Hand vs. machine trimming: quality, throughput, cost

- Environmental controls, QA, and product safety

- Tech stack: track‑and‑trace, metrics, and labeling

- Staffing, ergonomics, and safety

- Financial modeling: CapEx/OpEx and cost per pound

- Decision matrix: in‑house vs. outsource; wet vs. dry; hand vs. machine

- Site‑selection due‑diligence checklist

- Next steps and where to find properties

What “trimming and processing” include (and what they don’t)

Trimming and processing cover post‑harvest steps that convert dried or fresh cannabis into finished goods:

- Bucking & de‑leafing (removing flowers from stalks)

- Wet or dry trimming (shaping flower, removing excess leaf)

- Grading & sorting (A/B flower, littles, trim)

- Curing & conditioning (moisture/water activity targets)

- Packaging & labeling (retail jars, bulk, pre‑roll feedstock)

- Pre‑rolls & smalls (optional value‑add line)

This guide focuses on flower‑centric processing. Hydrocarbon/ethanol extraction involves different fire code and hazardous location rules; incorporate those only if your scope includes volatile solvents and design accordingly.

Cannabis trimming and processing fundamentals

Your primary variable is the product spec you sell (e.g., premium hand‑trimmed flower vs. value flower). Everything else—facility design, staffing, equipment, and SOPs—must align to that spec.

Key terms and control points (defined on first use):

- SOPs (Standard Operating Procedures): stepwise instructions that control variability.

- cGMP (current Good Manufacturing Practice): quality systems for consistent, clean product.

- HACCP (Hazard Analysis and Critical Control Points): risk‑based controls for safety.

- RH (Relative Humidity): % of water vapor in air at a given temperature.

- Water activity (aw): unbound moisture driving microbial risk; managed during cure/conditioning.

- AHJ (Authority Having Jurisdiction): your city/county building, fire, and planning departments.

- Track‑and‑trace (e.g., METRC): seed‑to‑sale compliance records tied to batches/lots.

Real estate, zoning, buffers, and permitting

Priority #1: Confirm a parcel or building is eligible for cannabis processing before you model the deal.

Land use & zoning

- Look for industrial/light‑industrial (I/L/I‑M), flex, or warehouse with clear path to processing/manufacturing as an allowed or conditionally allowed use.

- Many jurisdictions impose buffers from “sensitive uses” (schools, daycares, parks) and separation between cannabis uses. Buffer distances and whether they apply to processing—as opposed to retail—are AHJ‑specific. Validate with planning staff and your land‑use counsel.

Permits & approvals

- Planning: permitted use or CUP (Conditional Use Permit); sometimes a development agreement.

- Building: change of occupancy (common: F‑1/S‑1), tenant improvements, egress, restrooms.

- Fire: alarm/sprinklers; if extraction is present, hazardous exhaust, C1D1/C1D2 rooms.

- Environmental: odor control plan, solid waste plan, wastewater pre‑treatment if required.

- Business license and state license (processor/manufacturer/microbusiness, per your state).

Site features that reduce retrofit cost

- 200–400A+ power, 3‑phase where possible; roof structural capacity for HVAC.

- Floor drains with interceptor (if allowed), sealed concrete or food‑grade epoxy.

- Dock‑high or grade‑level loading with secure intake/ship areas.

- Odor control (carbon/HEPA), sealed rooms, and pressure differentials.

- Sufficient office, QA, storage, and employee welfare spaces (lockers, breakroom).

If you’re shopping for a facility, shortlist assets that can credibly host lease‑compliant properties and processing layouts. See cannabis processing facilities for sale on 420 Property.

Licensing path and compliance artifacts

Expect a 2‑step cadence: local approval first, then state licensure. Typical artifacts include:

- Security plan: controlled access, surveillance, alarm notifications, record retention.

- Odor mitigation plan: carbon filtration, negative pressure rooms.

- Waste plan: green waste handling, rendering, chain of custody, manifests.

- Operations plan: receiving, WIP (work‑in‑process) zones, trimming, packaging, sanitation.

- Quality plan: cGMP/HACCP programs, batch and lot definitions, hold‑and‑release, recalls.

- Track‑and‑trace procedures (e.g., METRC tag application, transfers, adjustments).

Because definitions and naming vary (processor vs. manufacturer), confirm with your state cannabis control agency and local AHJ before you commit capital.

Process flow & SOPs from harvest to packaged flower

1) Receiving & staging

- Verify batch IDs, weights, and COAs (if applicable). Quarantine until QA clears.

- Sanitize totes and carts. Document in batch records.

2) Bucking & pre‑trim

- Remove flowers from stalks. Target gentle handling to protect trichomes.

- Use stainless tables and food‑safe tools; sanitize per SOP frequency.

3) Trim path selection

- Wet trim: fast throughput, earlier odor loading, potential terpene loss if dried aggressively.

- Dry trim: more hang‑dry space/time; often preferred for premium flower morphology.

4) Curing & conditioning

- Control temp/RH and aw to your spec. Use data loggers; trend stability before release.

- Burp or equalize as needed; avoid stacking sealed bins that trap heat/moisture pockets.

5) Grading & sorting

- Calibrate graders on a standard photo set; avoid drift. Maintain “two‑person verification” on borderline calls.

6) Packaging & labeling

- Use cleanrooms or clean zones for jar/bag filling; verify scale calibration.

- Label controls: SKU, net weight, batch/lot, UID, pack date; barcodes tied to track‑and‑trace.

7) QA sampling & release

- Follow state sampling rules (who can sample, where, and how).

- Place finished goods in QA hold until COAs pass; document release in the ERP and track‑and‑trace.

Hand vs. machine trimming: quality, throughput, cost

Selecting the trimming modality is a brand decision with financial implications. Use the matrix and table below to align your choice with SKU, volume, and labor economics.

Decision drivers

- Brand promise: connoisseur whole‑flower vs. value flower.

- Volume volatility: seasonal spikes, harvest batching, or steady‑state perpetual harvest.

- Labor market: availability, training curve, turnover.

- OEE (Overall Equipment Effectiveness): uptime, changeovers, cleaning cycles.

- Total cost per finished pound: labor + consumables + depreciation + rework loss.

Comparison (illustrative ranges; validate with trials)

| Dimension | Hand Trim | Machine Trim |

|---|---|---|

| Typical throughput | ~1 lb/8‑hr shift per trimmer (varies by spec) | 10–19+ lb/hr dry depending on model and operator |

| Quality control | Highest control; artisan shaping | Modern machines preserve quality with correct moisture and feed rate |

| Labor | High, scalable via crew size | Low per pound; requires operator plus QA oversight |

| CapEx | Low | Moderate to high (machines + conveyors + cleaning tools) |

| Best for | Top‑shelf whole flower | Mid‑market flower, bulk, pre‑roll feedstock |

| Risks | Variable consistency; ergonomic strain | Over‑trim if settings/moisture are wrong; sanitation diligence required |

Implementation tips

- Pilot both approaches on the same batch to compare net yield, bag appeal, and rework.

- For machines, standardize moisture window and feed rate to prevent over‑processing.

- For hand crews, standardize tool sanitation and quality gates (e.g., 5% audit samples).

Environmental controls, QA, and product safety

Your processing rooms should behave like light food‑manufacturing environments.

- Air management: HEPA filtration for particulates; directional airflow; pressure differentials to keep dirty air out of clean zones.

- Sanitation: tool and surface sanitizers, color‑coded zones, scheduled deep cleans, and environmental monitoring where required.

- cGMP: document change control, deviations, corrective actions, and supplier qualifications.

- HACCP: map hazards (physical, chemical, biological), define critical limits (e.g., aw window), monitoring frequencies, and corrective actions.

- Ergonomics & noise: trimming lines can be repetitive and noisy. Build ergonomic stations and provide hearing protection where indicated by monitoring.

- Hold‑and‑release: nothing ships until QA signs off; maintain a recall‑ready documentation set.

Tech stack: track‑and‑trace, metrics, and labeling

- Track‑and‑trace integration: ensure your ERP/labeling ties UIDs to batches and finished goods; reconcile daily with your state system.

- Metrics: measure recovery (net flower %, smalls %, trim %), labor hours per finished pound, OEE, and QA fail rates. Trend by cultivar and harvest date.

- Label governance: one owner, version control, and pre‑press checks. Lock down allergen statements and warnings where required.

Staffing, ergonomics, and safety

- Roles: processing manager, QA lead, sanitation tech, receiving/fulfillment, trim operators (hand or machine), packaging leads, maintenance.

- Training: SOP sign‑offs, cGMP/HACCP basics, tool cleaning, foreign‑material control, and track‑and‑trace entries.

- Ergonomics: adjustable benches, anti‑fatigue mats, scheduled micro‑breaks, job rotation.

- PPE: gloves, sleeves, hair/beard covers, and hearing protection if noise exposure warrants it.

- Security: secured intake/ship doors, camera coverage of critical control points, and chain‑of‑custody for high‑value SKUs.

Financial modeling: CapEx/OpEx and cost per pound

A standardized model keeps decisions objective:

CapEx (illustrative categories)

- Facility TI: cleanable finishes, HVAC, filtration, small clean space.

- Equipment: buckers, trimmers (if used), conveyors, tables, scales, sealers, labelers.

- QA/IT: calibration tools, data loggers, ERP/label printers, barcoding.

OpEx

- Direct labor (bucking, trim, QA, packaging).

- Consumables (gloves, bags/jars, labels, CO₂/oxygen absorbers, cleaning chemicals).

- Utilities (HVAC, compressed air, lighting).

- QA/testing and sanitation.

- Repairs, maintenance, and downtime.

Cost per finished pound

- Start with harvested wet weight → dry recovery → grade split (A/B/smalls/trim).

- Allocate direct labor by timecard; add burden (payroll taxes/benefits).

- Depreciate equipment over useful life; apportion to units produced.

- Include QA fail/rework loss and finished goods shrink.

- Recalculate quarterly; use results to adjust SKUs, pricing, and trim modality.

Decision matrix: in‑house vs. outsource; wet vs. dry; hand vs. machine

A) In‑house vs. co‑packer (processor)

| If you prioritize… | Consider… | Why |

|---|---|---|

| Control over brand quality, rapid iteration | In‑house | Full control over specs, faster feedback loops |

| Speed to market, limited CapEx | Outsource select SKUs | Avoids immediate facility spend; converts fixed to variable cost |

| Licensing footprint, real estate leverage | In‑house | Facility adds asset value if jurisdiction is capacity‑constrained |

B) Wet vs. dry trim

| Factor | Wet | Dry |

|---|---|---|

| Throughput | Faster | Slower |

| Space | Less dry‑room space | More hang‑dry space |

| Bag appeal | Risk of scuff if rushed | Often higher whole‑flower appeal |

| Odor control | Higher immediate odor load | More distributed over cure cycle |

C) Hand vs. machine (see prior table; pilot and decide per SKU tier)

Site‑selection due‑diligence checklist

Use this to evaluate candidate properties and accelerate approvals:

- Zoning confirmation in writing; verify whether buffers apply to processing and what sensitive uses/measurements the AHJ recognizes.

- CUP/permits: required or by‑right? Timeline, conditions, and appeal risks.

- Fire/life safety: sprinklers, alarm, egress, and whether extraction is contemplated now or later.

- Utilities: 3‑phase power, HVAC tons, make‑up air, and water/sewer capacity; wastewater requirements.

- Odor control: ability to install carbon/HEPA and seal rooms; roof structural capacity for units.

- Floor plan fit: receiving, quarantine, buck/trim rooms, cure, packaging, QA hold, finished goods cage.

- Security: camera coverage, access control, and sightlines over docks and staging.

- Parking & logistics: employee count, vendor deliveries, discreet shipping.

- Neighbor compatibility: noise, odor, and hours of operation; documented mitigation.

- Futureproofing: room to add a pre‑roll line or nitrogen flush packaging; conduit/space for growth.

If you’re comparing lease vs. purchase for your processing plant, evaluate available cannabis businesses for sale and cannabis greenhouses for sale on 420 Property.

Myth vs. Fact

- Myth: “Machine trimming always ruins quality.”

Fact: With the correct moisture window, feed rate, and post‑trim QA, many operators hit retail specs via machine trim. Align the method with your brand tier and validate with sensory panels. - Myth: “Water activity is the same as relative humidity.”

Fact: They’re related but not identical. aw measures unbound water in the product; RH measures moisture in air. Control both to stabilize quality and mitigate microbial risk. - Myth: “Processing facilities don’t face buffers like retailers.”

Fact: Buffer rules are local and can apply to processing depending on the ordinance. Always confirm with your AHJ.

Next steps and where to find properties

- Map your SKU plan (premium flower, value flower, pre‑rolls).

- Choose your trim modality and build SOPs and QA gates.

- Underwrite 2–3 facilities with a side‑by‑side due‑diligence grid.

- Align on permits and timelines with the AHJ before you commit capital.

- Build your cGMP/HACCP program and train crews pre‑launch.

Action: Browse current listings to source properties that fit your zoning and utility profile, or to evaluate lease‑ready compliant properties for trimming and processing.

Disclaimer

This article is for educational purposes only and does not constitute legal, engineering, financial, or tax advice. Always consult qualified professionals and your local Authority Having Jurisdiction before making decisions.

Please visit:

Our Sponsor