Executive Summary (TL;DR)

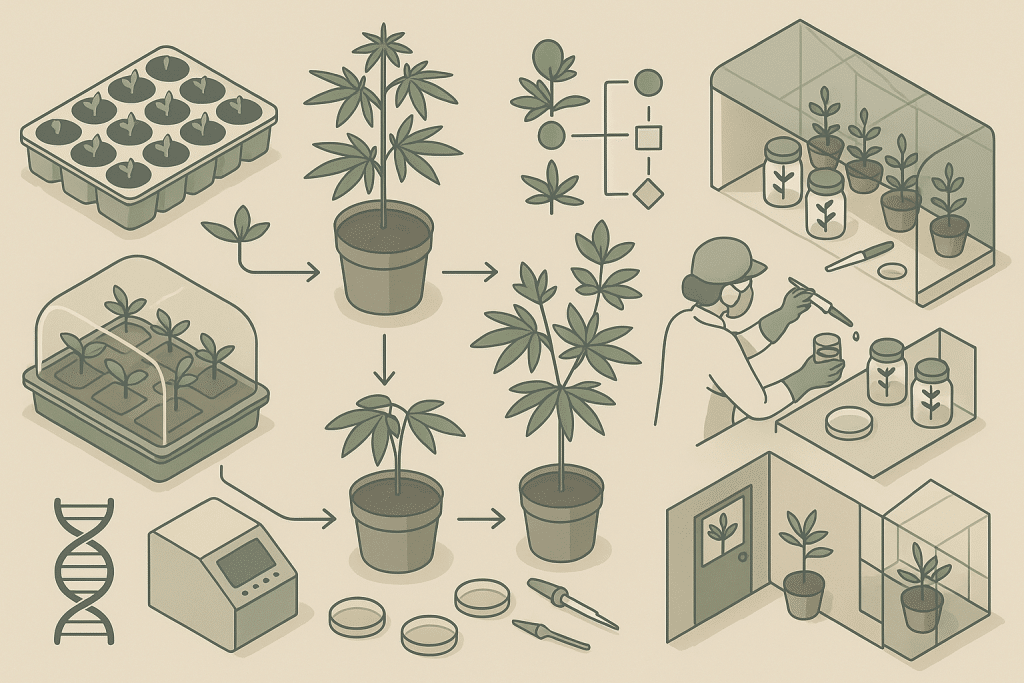

- Cannabis genetics is a business discipline, not a hobby. Your genetic strategy—seeds, breeding, clones, or tissue culture—determines yield stability, chemotype consistency, cost, and time-to-market.

- Start with regulatory fit and infrastructure: nurseries and microprop labs need the right zoning, buffers, and rooms (quarantine, clean zones, mother stock, acclimatization). If your current shell won’t support that, consider moving or acquiring capacity. → Browse compliant industrial grow spaces for lease

- Use a portfolio approach: F1 or day-neutral seeds for scalable production, elite clone lines for SKU consistency, tissue culture for clean stock, and marker-informed breeding to reduce guesswork.

- Protect value with SOPs for ** indexing (e.g., RT-qPCR for viroids), mother rotation, lot traceability, and COA-grade chemotype verification**.

- Decision: build a genetics program internally or acquire an operating nursery/cultivation business and plug in your IP. Both paths are viable if the plan is disciplined. → See cultivation/production businesses for sale

Table of Contents

- Why genetics is an executive decision

- Core vocabulary (fast)

- Seeds vs. clones vs. tissue culture: side-by-side comparison

- Breeding pathways that actually work (F1, backcross, line development)

- Clonal propagation & mother programs (without drift)

- Tissue culture & clean-stock pipelines (practical lab design)

- QA/Indexing: keep viroids, pathogens, and mix-ups out

- Facility & siting for genetics operations (zoning, buffers, rooms)

- KPI dashboard for genetics programs

- Myth vs. Fact

- Next steps and curated inventory

Why genetics is an executive decision

Your genetics program determines what your brand can promise and how reproducibly you can deliver it. The primary keyword here—cannabis genetics—touches capital allocation (build vs. buy), regulatory fit (can you legally operate a nursery or microprop lab at this address?), and time-to-revenue (seed-based scale-up vs. clone-based uniformity). Pick the wrong path and you inherit higher COGS, inconsistent chemotypes, and a recall-prone supply chain.

Operator’s lens: Treat genetics like SKU infrastructure. Standardize inputs, document your selections, and engineer a clean-stock backbone that makes production boringly predictable.

Core vocabulary (fast)

- Genotype / Phenotype / Chemotype: genetic code / expressed traits / chemical profile (cannabinoids & terpenes).

- Photoperiod vs. day-neutral (auto-flower): light-responsive vs. age-triggered flowering.

- Feminized seed: seed lots that produce predominantly female plants via sex-reversal pollination.

- F1 hybrid: first-generation cross of two inbred (or stabilized) lines; often exhibits heterosis (hybrid vigor).

- Backcross (BC1, BC2, …): crossing progeny back to a parent to fix a trait.

- IBL (inbred line): line bred to relative uniformity.

- MAS/GBS/SNP/SSR: marker-assisted selection, genotyping-by-sequencing, and common DNA markers for selecting traits.

- Micropropagation (tissue culture): in-vitro cloning under sterile conditions (initiation → multiplication → rooting → acclimatization).

- Meristem culture: apical shoot tip culture to eliminate systemic pathogens and viroids in regenerants.

Seeds vs. clones vs. tissue culture: side-by-side comparison

| Path | Best for | Strengths | Watch-outs | Real-estate & ops notes |

|---|---|---|---|---|

| Feminized seeds (photoperiod) | Scale, pheno exploration, lower inbound pest risk | Lower inbound contamination vs. clones; logistics easy; IP freedom for many crosses | Need pheno hunting & culling to lock uniformity; occasional intersex risk | Seed rooms + nursery benches; basic quarantine still required |

| Day-neutral (auto-flower) seeds | Outdoor/greenhouse cycles, rapid turns | Predictable flowering independent of daylength; mechanization friendly | Lower ceiling for certain premium flower SKUs in some markets | Site scheduling becomes calendar-driven; fewer blackout constraints |

| Elite clones | Premium indoor SKUs, precise chemotype | Uniform canopy & COAs; fast time-to-first harvest | Highest biosecurity risk (HLVd, pests) if intake is sloppy; mother drift | Must design quarantine & indexing; clean tool flow; mother rotation plan |

| Tissue culture (clean-stock) | Reset infected lines; long-term germplasm storage | Pathogen/viroid cleanup; compact storage; stable resets | Requires trained staff, CAPEX, and acclimatization skill; some genotypes are recalcitrant | Need microprop lab, greenhouse hardening space, and clean workflow |

Operator takeaway: Most durable programs combine F1 or day-neutral seeds for bulk with clone-based premium lines and a tissue-culture “reset” capability to protect mother libraries.

Breeding pathways that actually work (F1, backcross, line development)

1) Define target traits and proof.

Link traits (yield per sq-ft per day, bud structure, trichome density, harvest window, resistance signals) to measurement SOPs so breeding selections are evidence-based.

2) Stabilize parents, then make F1s.

Stabilize parental lines toward uniformity before crossing. F1s often deliver heterosis (vigor, uniformity). For day-neutral breeding, incorporate the flowering-time locus that confers age-triggered onset.

3) Backcross & line selection.

Use BC1/BC2 to fix a standout trait (e.g., terpene profile) while recovering the rest of the recurrent parent genome. Select with SNP/SSR markers or GBS to compress cycles and reduce “looks good but segregates later” surprises.

4) Make it shippable.

Before scaling a line to customers or internal farms, document germination, uniformity, stress tests (heat, low VPD), and COA repeatability in three environments.

5) Feminized seed production (responsibly).

Use validated sex-reversal methods (e.g., silver thiosulfate, STS) on chosen females, collect pollen, and perform controlled pollinations. Benchmarks in horticulture literature describe reliable feminization with proper timing and concentration; include off-type auditing (male rate, intersex checks) before release.

Clonal propagation & mother programs (without drift)

Mother strategy

- Keep mother rotation tight (e.g., retire after a set number of cut cycles) to avoid physiological decline.

- Run a clean-to-dirty workflow: intake/quarantine → mothers → propagation → veg → flower. Never backtrack upstream without gowning changes.

Cutting SOP highlights

- Single-use blades or bleach (5–10%) + dry heat 320°F/160°C for 10 min between plants. Ethanol or peroxide alone are not reliable against viroids such as HLVd.

- Gloves per bench; sanitize benches/trellis; staged spray bottles for tool dips; replace bleach solution every 2 hours.

Intake

- Quarantine inbound clones; RT-qPCR index for HLVd (two negatives, 7–14 days apart); verify pest-free status; keep lot traceability.

Tissue culture & clean-stock pipelines (practical lab design)

Lab flow: receiving → surface sterilization → meristem initiation → multiplication on cytokinin-rich medium → rooting (auxin-rich) → acclimatization (high humidity, step-down light). Use Murashige & Skoog (MS)-based media with cultivar-specific plant growth regulators (e.g., BAP for shoot induction; IBA/NAA for roots).

Where tissue culture shines

- Pathogen/viroid cleanup: meristem therapy plus thermotherapy can recover true-to-type, viroid-free regenerants in many cultivars.

- Germplasm storage: slow-growth storage or cryo-beads for long-term backup of elite IP.

- Uniform starter blocks: synchronized batches reduce canopy variance.

Common pitfalls

- Recalcitrance (some genotypes multiply slowly).

- Phenotypic drift if protocols aren’t tight; reduce somaclonal variation by minimizing callus phases and cycles.

- Hardening losses without gradual humidity/light transitions.

QA/Indexing: keep viroids, pathogens, and mix-ups out

- RT-qPCR indexing cadence: mothers every 2–4 weeks; inbound lots on arrival and again prior to release; symptomatic benches on demand. Use labs that include internal amplification controls to catch inhibitors.

- Identity & chemotype controls: DNA fingerprinting (SSR/SNP panel) for elite lines, periodic terpene/cannabinoid profiling to confirm SKU integrity.

- Records: lot IDs, sampling maps, COAs, and destruction logs for positives.

- Training & audits: weekly observation of blade/glove cadence; bleach expiration logs; heat-cycle verification; quarantine door logs.

Facility & siting for genetics operations (zoning, buffers, rooms)

Zoning & buffers

- Nurseries and tissue-culture facilities typically fit industrial or agricultural districts, but cannabis uses are often treated separately. Confirm permitted vs. conditional status with your Authority Having Jurisdiction (AHJ) and document buffer distances (commonly 600–1,000 ft to sensitive uses) and the exact measurement method (property-line, entrance-to-entrance, or parcel centroid).

- For multi-license sites (retail + nursery), ensure the plan accommodates ADA Title III for public-facing areas and life-safety requirements.

Room program

- Quarantine intake with nearby sampling station.

- Mother & propagation rooms upstream of production.

- Microprop lab with sterile hood(s), media room, growth room, and acclimatization space.

- Sanitation stations (chemical + dry heat) in each zone.

- Waste flow that never crosses clean corridors.

When the shell fights you

If your current building won’t support line-of-travel, quarantine, or lab separation, rehab costs and infection risk rise. Solve with a better shell or by acquiring a clean operating asset:

→ Industrial/warehouse for sale

→ Operating cultivation/production businesses

KPI dashboard for genetics programs

Track weekly and publish to the team:

- Mother health index (age in cut cycles, cut quality score).

- Indexing cadence compliance (mothers/inbound lots).

- HLVd/Pest findings (rooms affected; CAPA status).

- Seed lot QA (germ %, off-type %, feminization success %, intersex observations).

- Clone lot QA (rooting %, days to transplant, early vigor score).

- Tissue culture (multiplication rate, contamination %, acclimatization survival %).

- SKU integrity (chemotype drift alarms; DNA fingerprint matches).

- Cost per start (seedling/clone/microprop), time-to-ready, and losses by stage.

Myth vs. Fact

- Myth: Feminized seeds always produce 100% female plants.

Fact: Properly executed programs are highly female-biased, but off-types and intersex must still be monitored and culled; QA belongs in every seed lot. - Myth: Tissue culture guarantees zero drift.

Fact: TC is a powerful clean-up and storage tool, but poor protocols can induce somaclonal variation. Tight SOPs reduce risk. - Myth: A mother room is “clean” if plants look healthy.

Fact: HLVd and other pathogens can be asymptomatic for weeks; indexing and tool hygiene matter more than appearance. - Myth: Seeds equal inconsistency; clones equal perfection.

Fact: Well-bred F1 seed can outperform sloppy clone programs on uniformity and cost. Clones shine when mother care and indexing are excellent.

Next steps and curated inventory

- Decide the portfolio split (F1/day-neutral seeds for scale + clones for premium + TC for reset).

- Stand up clean intake and indexing (quarantine bays, RT-qPCR cadence, DNA/chemotype checks for elite lines).

- Map your rooms & flow for mother/propagation and tissue culture; fix the shell or move.

- Operationalize: publish SOPs (cutting, sanitation, acclimatization, mother retirement), track KPIs weekly.

- Accelerate with existing assets if timing matters.

Disclaimer

This article is for educational purposes only and does not constitute legal, engineering, financial, or tax advice. Always consult qualified professionals and your local Authority Having Jurisdiction before making decisions.

Please visit:

Our Sponsor