Executive Summary (TL;DR)

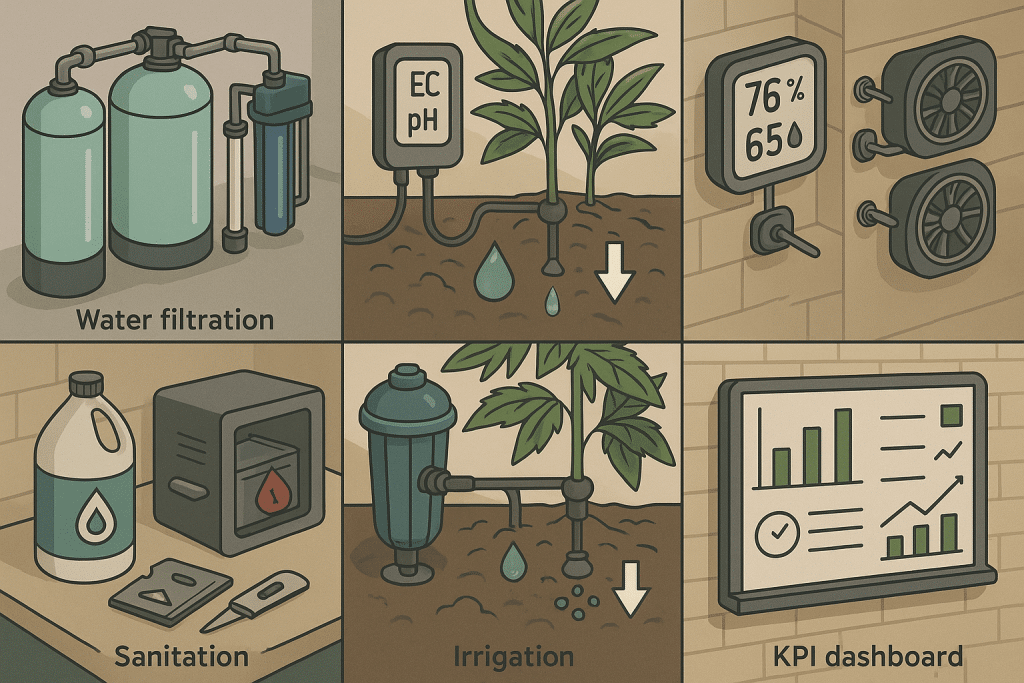

- Most cannabis grow problems trace back to a few controllable systems: water quality (pH/alkalinity, EC), fertigation discipline, airflow/VPD, sanitation, and workflow design. Tightening these systems prevents 80–90% of costly failures.

- Start with infrastructure. If your current shell can’t support treatment skids, sanitation stations, and clean→dirty flow, it will keep taxing yields and labor. When speed matters, inherit capacity. → Browse compliant industrial grow spaces for lease

- Diagnose fast and fix with playbooks: water tests → recipe/pH corrections; VPD and airflow baselines; validated sanitation for viroid/pest vectors; and a weekly KPI huddle (feed vs. drain EC/pH, runoff %, VPD uptime, clog rate).

- Protect margin: prevention is cheaper than remediation. Build SOPs for intake, tool hygiene, sensor calibration, and end-of-day flushes. Budget for testing and keep a clean-stock pipeline.

Table of Contents

- Root causes behind most crop issues

- Prevention architecture (the 6-system model)

- Fast diagnostics (decision tree)

- Solutions by problem (tables you can use)

- Facility & siting considerations (zoning, buffers, build-outs)

- KPI dashboard & weekly operating rhythm

- Quick-start SOPs (ready to deploy)

- Next steps and curated inventory

Root causes behind most crop issues

Despite how many symptoms you see—leaf edge burn, interveinal chlorosis, weak set, bud rot, dud phenotype—the root causes cluster into a small set:

- Unmanaged source water (high alkalinity/hardness, sodium/chloride, iron/manganese, microbes) driving pH drift, precipitation, and clogs. Authoritative greenhouse guidance recommends testing pH, alkalinity, EC/Conductivity, hardness, chloride, and sodium at minimum; many programs target finished-water alkalinity ≤50 ppm as CaCO₃ to stabilize pH in media. Penn State ExtensionUMass Amherst+1

- Fertigation and drainage errors (inflow EC/pH out of range; insufficient runoff; inconsistent pulse timing) that cause salt accumulation or hypoxia.

- Airflow & VPD imbalance (dead zones, poor mixing, humidity spikes) leading to powdery mildew/botrytis pressure and slowed metabolism.

- Sanitation gaps that let mechanically transmitted pathogens (e.g., hop latent viroid, HLVd) spread via blades/gloves/benches or through shared solutions. Validated inactivation uses bleach and dry-heat, not ethanol. OSU Extension Service

- Irrigation hardware (filtering/flush discipline) that lets biofilm/precipitates clog emitters, creating canopy variability. UC ANR details filtration/sanitation to prevent biological and chemical clogging. UC Agriculture and Natural Resources+1

- Facility constraints (no quarantine bay, no space for treatment skids, recirculation without disinfection) that keep problems chronic.

Prevention architecture (the 6-system model)

Build a prevention stack once and keep it boringly reliable.

1) Water & Chemistry

- Test quarterly (or when sources change) for pH, alkalinity (as CaCO₃), EC/TDS, hardness Ca/Mg, sodium, chloride; add metals and SAR when warranted. Penn State Extension

- If alkalinity is high, install carbon → RO → storage → UV/ozone. Blend/re-mineralize to the recipe; hold finished-water alkalinity near 0–50 ppm CaCO₃ to minimize drift. UMass Amherst

- Keep sanitation upstream of injectors to avoid nutrient reactions.

2) Fertigation & Drain Control

- Phase targets (illustrative, tune to cultivar/substrate):

- Veg: inflow EC 1.2–2.0 mS/cm; pH 5.7–6.3 (inert) or 6.2–6.6 (soil/peat).

- Flower: 1.8–2.6 mS/cm with steady pH; 10–20% runoff for coco/rockwool to manage salts.

- Log drain EC/pH daily; rising drain EC indicates salt buildup; falling with high runoff indicates over-leach.

3) Airflow, VPD & Canopy Hygiene

- Balance supply/return, remove dead zones, and map VPD at canopy level.

- Stagger defoliation and maintain dry zones around wounds.

4) Sanitation & Biosecurity

- Work clean → dirty (quarantine → mothers → propagation → veg → flower → trim/waste).

- Blade hygiene: single-use blades when possible; otherwise bleach (5–10% sodium hypochlorite) + dry heat 320°F/160°C for 10 min between plants; ethanol/peroxide/autoclave are not reliable for HLVd. OSU Extension Service

- Weekly line flushes; reservoir cleaning and verified oxidant contact times.

5) Irrigation Hardware & Filtration

- Size primary/secondary filters; avoid forgotten in-line screen washers or add them to the inspection route (they clog fast). UC Agriculture and Natural Resources

- Monitor pressure differential; flush laterals on a calendar; keep spares.

6) OSHA HazCom & Records

- Maintain SDS for acids/bases/sanitizers; GHS labels; eyewash/shower access; annual training. OSHA+1

Fast diagnostics (decision tree)

- Symptom scope

- Whole room/bench? → suspect water/EC/pH/airflow/hardware.

- Random plants? → suspect sanitation, pests/pathogens, or emitter-level clogs.

- Measure fundamentals (same day)

- Inflow EC/pH vs. drain EC/pH (3–5 points per bench).

- VPD and airspeed at canopy, morning & late day.

- Source & finished-water alkalinity/EC; reservoir DO/temperature if hydro.

- Sanitation audit

- Observe blade/glove change cadence; check bleach age; verify heat cycle.

- Inspect filters and pull emitter samples for clog type (biofilm vs. precipitate).

- Action

- If drain EC high → increase runoff or reduce inflow EC; flush; reset.

- If pH drift → lower alkalinity (blend RO, adjust acid dosing).

- If clogs → clean/replace emitters; service filters; sanitize lines (per UC ANR guidance). UC Agriculture and Natural Resources

- If dudding symptoms → index mothers/clones by RT-qPCR; implement bleach+heat tool SOP; rebuild stock as needed. OSU Extension Service

Solutions by problem

A) Yellowing or interveinal chlorosis (mid-canopy)

Likely causes: High media pH from alkalinity; Mg or Fe availability issues; salt accumulation.

Fixes:

- Verify finished-water alkalinity (target ≤50 ppm CaCO₃); adjust acid; use RO blend. UMass Amherst

- Correct inflow pH into substrate window; add Mg if coco-related antagonism suspected; flush to reset salts.

B) Tip burn & weak stems in early flower

Likely causes: K over-aggression suppressing Ca; EC spikes; airflow dead zones.

Fixes:

- Rebalance recipe to keep Ca strong through stretch; soften EC step-ups; add mixing fans to eliminate microclimates.

C) Powdery mildew / botrytis pressure

Likely causes: Humidity spikes at lights-off; poor air mixing; wet microclimates.

Fixes:

- Stagger irrigation earlier; maintain VPD through transitions; add targeted air movement; prune for airflow.

D) Random “dud” plants; weak resin; poor yield

Likely causes: HLVd spread by tools/hands or co-rooting/shared solution.

Fixes:

- Index mothers/inbound clones by RT-qPCR; quarantine positives; bleach + dry heat tool SOP; stop co-rooting; sanitize recirc systems; rebuild stock (meristem/clean vendor lots). OSU Extension Service

E) Uneven canopy / chronic dry spots

Likely causes: Emitter clogs; under-filtered water; line pressure differences.

Fixes:

F) Recirculated solution smells / biofilm

Likely causes: Insufficient disinfection; warm reservoirs; organic load.

Fixes:

- UV/ozone or appropriate oxidant with contact time; lower solution temp; improve filtration; schedule full reservoir sanitation.

Facility & siting considerations (zoning, buffers, build-outs)

Even the best SOPs struggle in the wrong address.

- Zoning & use: Confirm cultivation/manufacturing is permitted or conditional in the district; some municipalities apply cannabis buffers (commonly 600–1,000 ft to sensitive uses). Get the measurement method in writing from the Authority Having Jurisdiction (property-line vs. entrance-to-entrance).

- Biosecurity layout: Plan for quarantine bays, mother & propagation rooms upstream, tool-bake/bleach stations in each zone, and cleanable surfaces.

- Water and discharge: If you install RO and sanitize/flush lines, coordinate with your local control authority; nutrient-bearing purge or RO brine can fall under the National Pretreatment Program (discharge to POTW) within the NPDES framework. US EPA+2US EPA+2

- When to move: If your shell can’t support the flow you need, rehab costs balloon. Consider a new shell or acquire a running operation and retrofit SOPs.

KPI dashboard & weekly operating rhythm

Measure what you manage; review every week.

- Feed vs. drain EC/pH (by room/zone)

- Runoff % (coco/rockwool); SME or paste extracts for soil/peat

- Finished-water alkalinity; acid use per 1,000 gal

- Clog rate (% emitters replaced); pressure differential across filters

- VPD uptime (% of hours in target) and canopy airspeed map updates

- Sanitation events (reservoir clean, line flush, tool SOP compliance %)

- Indexing cadence (mothers/inbound lots tested; HLVd status)

- Yield & grade distribution; cannabinoid/terpene averages

Quick-start SOPs (ready to deploy)

1) Daily Sensor Calibration & Record

- Calibrate pH (2-point) and EC probes at open; log slope/offset; replace if drift exceeds threshold.

- Verify finished-water EC/alkalinity and inflow EC/pH match recipe.

2) Blade & Glove Discipline

- Single-use blades preferred; otherwise bleach (5–10%) + 10-min dry heat at 320°F between plants. Refresh bleach every 2 hours; log cycles. Ethanol/peroxide/autoclave are not reliable for HLVd. OSU Extension Service

- New gloves for each bench or after each sanitation cycle; gowns per room; never backtrack upstream.

3) End-of-Day Line Hygiene

4) Weekly Filter & Emitter Maintenance

5) Intake & Quarantine

- Test inbound clones/mothers via RT-qPCR; quarantine until two negatives 7–14 days apart; keep lot records.

Next steps and curated inventory

- Run a 48-hour audit: water tests, feed vs. drain EC/pH, VPD map, sanitation observation.

- Close the biggest gap first: if alkalinity is high, install treatment; if sanitation is weak, deploy bleach+heat SOP; if hardware is failing, overhaul filters/emitters.

- Fix the shell if it’s the bottleneck—or acquire capacity that already runs the way you need.

Disclaimer

This article is for educational purposes only and does not constitute legal, engineering, financial, or tax advice. Always consult qualified professionals and your local Authority Having Jurisdiction before making decisions.

Please visit:

Our Sponsor