Executive Summary (TL;DR)

- Cannabis nutrients & feeding is an operating system, not a product line. Your results come from stable inputs (water chemistry), fit-for-substrate recipes, precise EC/pH control, disciplined pulse schedules, and post-run checks—not from “magic bottles.”

- Priority #1 is water quality: characterize pH, alkalinity (as CaCO₃), EC/TDS, hardness, sodium/chloride, iron/manganese, and microbes. Most indoor programs target finished-water alkalinity ≤50 ppm CaCO₃ so pH doesn’t drift upward in media.

- Design for repeatability and safety: clear phase targets, a published feeding schedule, labeled concentrate tanks (A/B/Micro), calibrated sensors, and OSHA HazCom (29 CFR 1910.1200) basics—SDS access, secondary containment, PPE, eyewash, and training.

- Yield and potency are shaped by availability and balance (Ca/Mg/K, N:K over time), oxygen at the root zone, runoff management, and stress avoidance. Small, frequent pulses at controlled EC with healthy drain patterns beat “feast-or-famine.”

- Site choice still matters: you’ll need power, floor drains, room for treatment/skids, and compliant chemical storage. If speed is the goal, inherit infrastructure. → Find industrial grow spaces for lease

Table of Contents

- Why nutrients & feeding determine potency, quality, cost, and yield

- Inputs first: water chemistry, sanitation, and compliance

- Nutrient ratios & feeding schedules by phase (soil, coco, hydro)

- Fertigation design: tanks, injection, controls, and OSHA SDS (HazCom)

- Sample Feeding SOP (ready to adopt)

- Yield and potency impact: what moves the needle

- Cost model and KPI dashboard

- Facility requirements: zoning, buffers, backflow, and discharge

- Due-diligence checklist (water → room → SOPs)

- Decision matrix: choose and tune your program

- Next steps and curated inventory

Why nutrients & feeding determine potency, quality, cost, and yield

Feeding is process control. It governs metabolism, canopy development, flower set, and secondary metabolite expression (terpenes/cannabinoids). On the P&L, it shapes cost per pound through:

- Rework and loss from pH/EC mistakes (lockout, burn, weak set).

- Labor tied to troubleshooting clogs and inconsistent drains.

- Runoff & water waste when chemistry drifts beyond targets.

- Grade distribution (A/B/trim) driven by uniformity and stress avoidance.

Your target state: predictable plant-available nutrition at the root zone, tight phase-appropriate EC, and stable pH—delivered with a pulse strategy the team can execute every day.

Shortcut option: If time-to-yield matters, buy into running capacity where fertigation and storage are already permitted and commissioned. → Evaluate cultivation & production businesses for sale

Inputs first: water chemistry, sanitation, and compliance

Why water quality is the master variable

Media pH drifts upward when alkalinity is high, and key ions (Ca/Mg/Fe) can precipitate or antagonize uptake if the recipe ignores source water. Treat water like a raw material:

- Baseline panel: pH, alkalinity, EC/TDS, hardness (Ca/Mg), sodium, chloride, iron/manganese, nitrate, boron (as needed), and microbial indicators.

- Targets: For many indoor programs, a finished water alkalinity of 0–50 ppm as CaCO₃ stabilizes pH and reduces acid consumption.

- Common stack: Sediment → carbon (chlorine/chloramine removal) → RO → storage → UV/ozone sanitation → blend and dose.

- Sanitation placement: Disinfect upstream of injectors so oxidants don’t attack chelates or react with nutrients.

Compliance hooks you can’t ignore

- Backflow prevention: Municipal supply commonly requires a testable backflow assembly; annual testing is routine.

- Waste/discharge: RO brine and nutrient-bearing purge might require pretreatment or permitting (local control authority; NPDES context).

- Storage & labeling: GHS-compliant labels on concentrates and acids/bases; segregate incompatible chemicals; ventilate per code.

Nutrient ratios & feeding schedules by phase (soil, coco, hydro)

Cannabis nutrients & feeding strategy aligns three levers: ratio, EC, and timing—with substrate-specific pH windows and runoff rules.

Ratios that make sense (illustrative baselines)

Use these as starting points to be tuned with tissue/solution tests and batch feedback. Ratios are expressed as elemental approximations, not oxide labels.

| Phase | N | P | K | Ca | Mg | S | Micronutrients | Notes |

|---|---|---|---|---|---|---|---|---|

| Propagation | Low (0.5–1.0 EC) | Very low | Low | Moderate | Moderate | Low | Fe/Mn/Zn/B adequate | Focus on root & meristem health; avoid excess ammonium |

| Veg (early) | Medium | Low | Medium | Medium–High | Medium | Medium | Maintain full micro suite | Rapid growth; watch Ca for new tissue integrity |

| Veg (late) | Medium–High | Low–Med | Medium–High | High | Medium | Medium | Keep Fe/Mn robust | Prepare for transition; protect Ca/Mg balance |

| Flower (early) | Medium | Medium | High | High | Medium | Medium | Avoid micro shortages | Increase K and modest P; don’t crash N too fast |

| Flower (mid/late) | Medium-Low | Medium | High | High | Medium | Medium | Keep Zn/B steady for flower formation | Manage salt load; maintain Ca for structure |

Ca:Mg: Many programs target Ca:Mg ≈ 2:1 (by elemental ppm) across veg/flower to protect tissue quality and reduce blossom-end-type disorders.

N forms: Favor nitrate over ammonium in warm rooms to avoid soft growth and pH swings.

Feeding schedules (phase EC/pH & pulse cadence)

Soil / Soilless (peat-based)

- pH (inflow): 6.2–6.6

- EC (inflow): 0.8–1.2 (prop), 1.2–2.0 (veg), 1.8–2.4 (flower)

- Cadence: Larger irrigations less frequently vs. coco; monitor SME (saturated media extract) to keep media EC in range.

- Runoff: Periodic leach to reset salts; avoid chronic oversaturation.

Coco

- pH (inflow): 5.9–6.4

- EC (inflow): 1.2–2.0 (veg), 1.8–2.6 (flower)

- Cadence: Pulse 3–6x/day in flower with short events; aim 10–20% runoff to manage salts.

- Special: Front-load Ca/Mg; coco’s cation exchange binds them.

Rockwool / Inert Hydroponics

- pH (inflow): 5.6–6.2

- EC (inflow): 0.6–1.0 (prop), 1.3–1.9 (veg), 1.9–2.6 (flower)

- Cadence: Many short pulses tied to slab weight (drain start at ~70–80% of field capacity; tune by room).

- Recirculation: Add UF/UV/oxidant sanitation; watch pathogen risk.

Drain discipline: Track drain EC and pH daily. Rising drain EC = salt accumulation (increase runoff or lower inflow EC). Falling drain EC = over-leach (back off runoff or raise inflow EC slightly).

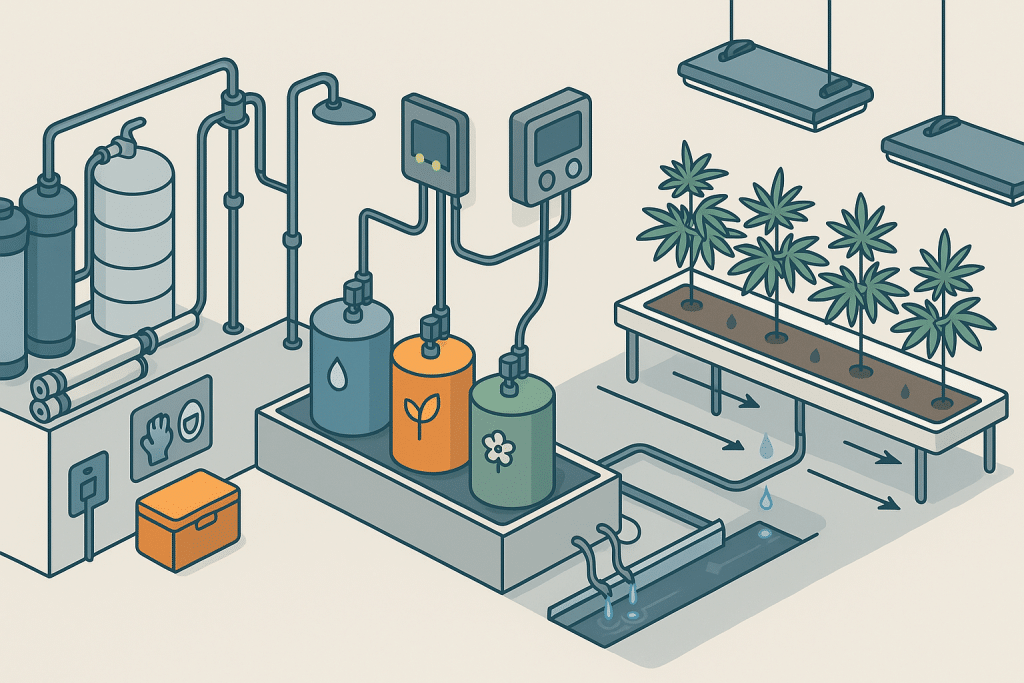

Fertigation design: tanks, injection, controls, and OSHA SDS (HazCom)

Mixing & storage fundamentals

- Keep incompatible ions apart: Classic A/B split keeps Ca away from phosphates/sulfates. A third “Micro” tank often carries Fe/chelated micros to protect stability.

- Agitation: Use slow mixers; avoid heat that accelerates precipitation.

- Secondary containment: Size to code; segregate acids and bases; label every vessel with contents, concentration, and last verification date.

Injection & distribution

- Technology choices: Venturi injectors, diaphragm/stepper dosers, or proportional injection skids. Prioritize accuracy, chemical compatibility, part availability, and ease of calibration.

- Sensors: Inline EC and pH with daily slope checks; keep spares and fresh solutions. ORP if oxidants are used upstream.

- Pulsing: Short, frequent events protect oxygen and EC stability. Automate by drain weight/slab EC where sensors exist; otherwise by time windows validated against drains.

Controls & alarms

- Interlocks: Pause fertigation on out-of-range pH/EC, empty tank alarms, or sensor failure. Require supervisor acknowledgment to resume.

- Data logging: Recipe version, batch/lot, operator ID, pre/post EC/pH, drain EC/pH, and exception notes.

- Flush logic: Automated end-of-day flush to clear lines and discourage biofilm.

OSHA SDS & HazCom essentials (29 CFR 1910.1200)

- SDS access: Maintain Safety Data Sheets for every nutrient, acid/base, sanitizer, and cleaner in a known location (digital or binders) and accessible to all shifts.

- Labels & pictograms: GHS-compliant containers; do not decant into unlabeled bottles.

- Training: HazCom training on chemical hazards, PPE, handling, first aid, spill response, and eyewash/shower use; refresh at hire and annually.

- PPE: Gloves compatible with acids/bases, splash goggles/face protection, aprons, and closed-toe footwear.

- Emergency gear: Eyewash/shower stations within 10 seconds of chemical mixing; spill kits and neutralizers staged and inspected.

- Segregation: Store oxidizers away from organics; keep acids/bases apart; ventilate storage per code.

Sample Feeding SOP (ready to adopt)

Purpose

Provide standardized steps to prepare, verify, and deliver nutrient solution to crop zones with stable EC/pH and compliant safety practices.

Scope

Applies to all cultivation rooms and all personnel who mix, verify, or deliver feed solutions.

References

- Company Fertigation Standards (current version)

- OSHA Hazard Communication (29 CFR 1910.1200)—SDS & training

- Backflow assembly test report (current year)

- Water treatment operations manual

Responsibilities

- Fertigation Lead (FL): Owns recipe, calibration, verification, and sign-off.

- Technician (FT): Executes mixing, monitors delivery, logs drains, reports anomalies.

- Safety Officer (SO): Verifies SDS access, PPE, eyewash/spill readiness.

A. Pre-run checks (15–20 min)

- SDS & PPE: Confirm SDS access. Don PPE (gloves, goggles/face shield, apron).

- Room status: Confirm rooms/zones scheduled to feed; verify irrigation valves functional.

- Sensor health: Calibrate EC and pH probes (document slope and offset). Replace or clean if drift > allowable limits.

- Water treatment: Check RO permeate EC (<0.1–0.2 mS/cm target) and storage level; confirm UV/ozone running.

- Tanks: Verify A/B/Micro stock volumes; check labels and concentrations; inspect mixers.

B. Batch preparation (30–45 min)

- Recipe selection: Select phase-appropriate recipe (e.g., Veg-Late v3.2).

- Fill mix tank with target volume of treated water.

- Dose order: Add Micros → B (phosphates/sulfates) → A (calcium source), mixing between additions.

- Pre-pH check: Measure pH; if high, dose acid to land in target window; if low, dose base carefully.

- Target EC/pH: Adjust to setpoints (e.g., EC 2.1 mS/cm, pH 5.9 coco / 6.3 soil). Record.

- Stability hold: Mix for 5 minutes; re-measure EC/pH to confirm stability (±0.05 pH, ±0.05 mS).

- Sample retain: Pull a 100 mL sample, label with batch ID, date/time, operator initials.

C. Delivery (pulse schedule)

- Start window: Initiate first pulse after lights-on + 1–2 hours (confirm facility strategy).

- Pulse parameters:

- Coco: 3–6 pulses/day in flower; 1–3 in veg.

- Rockwool: weight-based control; aim to start drains when slabs reach 70–80% FC.

- Soil/peat: fewer, larger irrigations; confirm container mass and drain pattern.

- Runoff target: Achieve 10–20% drains (coco/rockwool); as scheduled for soil media.

- Drain logging: After the second pulse and mid-cycle, record drain EC/pH for each representative zone.

D. Post-run checks

- Trend review: If drain EC > inflow EC persistently, increase runoff or reduce inflow EC slightly. If drain EC < inflow EC with high runoff, back off runoff or raise inflow EC marginally.

- Line hygiene: End-of-day flush per program (clean water or low-dose sanitizer if scheduled).

- Documentation: Complete batch log with recipe version, setpoints, actuals, drains, anomalies, and CAPA if out-of-range.

- Housekeeping: Wipe spills, stage spill kit, confirm eyewash test performed as scheduled.

Deviation handling

- If EC/pH drift exceeds tolerances or drains show rapid salting, notify FL immediately; quarantine impacted zones for follow-up pulse adjustments.

- Record CAPA: cause, correction, prevention step, and verification date.

Yield and potency impact: what moves the needle

You’ll rarely “bottle your way” to top tier outcomes. Most gains come from availability, balance, and stress control:

- Availability: Stable pH in the media’s preferred range keeps P, Fe, Mn, and Zn soluble; alkalinity-induced pH creep locks them out.

- Balance: Ca/Mg/K antagonisms are common. Over-aggressive K in early flower can depress Ca uptake (brittle growth, tip burn). Keep Ca robust throughout, Mg steady, K rising into mid/late flower.

- Oxygen: Frequent, modest pulses reduce hypoxia risk in the rhizosphere; roots under low O₂ stall, reducing carbohydrate flow to flowers.

- Runoff management: Drains are your early-warning system. Keeping drain EC close to inflow EC prevents salt toxicity that hurts grade distribution.

- Stress avoidance: Sudden N crash at week 3–4 or a pH overshoot can set plants back; dial transitions over several irrigations.

- Genotype reality: Some cultivars demand higher Ca/Mg; others are salt-sensitive—record, learn, and adjust a per-cultivar overlay to your base program.

The net: consistency beats novelty. Controlled inputs, tight drains, and gradual transitions challenge far fewer flowers off A-grade and protect terpenes.

Cost model and KPI dashboard

Model the full cost, not just bottles:

- Capex: Treatment (RO + storage), injectors/dosers, sensors, controls/SCADA, secondary containment, plumbing, and drains.

- Opex: Salts/liquids (or dry nutrients), acids/bases, filter/membrane replacements, sanitation chemicals, probe solutions/lamps, energy, labor, and lab tests.

- Hidden costs: Emitter clogs, troubleshooting time, throw-away batches, pH/EC-induced stress (lost grade), wastewater fees.

- Yield/quality value: Track cannabinoid/terpene outcomes by room and recipe version; quantify grade lift.

Weekly KPIs

- Feed EC/pH vs. drain EC/pH (per zone).

- Runoff % and drift trend.

- Alkalinity (finished water) and acid use per 1,000 gal.

- $ per gallon of finished feed and nutrient $/lb (finished flower).

- Clog rate (% emitters replaced) and sanitation events completed.

- Deficiency/excess flags and CAPA closure rate.

- Batch cycle hits (on-time pulses vs. missed windows).

Facility requirements: zoning, buffers, backflow, and discharge

You mix and store chemicals inside someone’s jurisdiction:

- Zoning & buffers: Cultivation and fertigation rooms typically belong in industrial districts; many AHJs require 600–1,000 ft separation from sensitive uses. Confirm the measurement method (property-line, entrance-to-entrance, parcel centroid) in writing with planning staff.

- Backflow & cross-connection: Expect a testable backflow assembly and annual testing; log results.

- Discharge: Coordinate with your local control authority on RO brine and nutrient purge; pretreatment or permits may apply.

- Storage: Secondary containment volumes per code; segregate acids/bases/oxidizers; ventilation and signage; keep SDS and spill kits visible.

- ADA & life safety: If the facility has a public interface (e.g., co-located dispensary), factor upgraded routes, clearances, and counters into TI plans.

If your current shell cannot house treatment skids, storage, or containment cost-effectively, consider relocating to a better-fit building or acquiring one designed for controlled-environment ag. → Review warehouse/industrial properties for sale

Due-diligence checklist (water → room → SOPs)

Water & treatment

- Lab panel within 90 days; finished-water alkalinity ≤50 ppm CaCO₃ target validated.

- Treatment P&IDs; RO performance logs (permeate EC), UV/ozone maintenance.

- Backflow assembly model, test date, and pass result.

Fertigation & SOPs

- Phase recipes; A/B/Micro tank maps; incompatibility matrix (Ca vs. phosphates/sulfates).

- Calibration log (daily EC/pH checks, slope/offset), spares on hand.

- Pulse schedule by substrate; runoff policy; drain EC/pH logs by zone.

- End-of-day flush and weekly sanitation SOPs.

Safety & HazCom

- SDS binders/digital access; onboarding and annual HazCom training records; eyewash/shower test logs.

- Secondary containment calculations; chemical inventories and segregation; spill response plan and drills.

Performance

- 6–12 months of yield/grade distributions, cannabinoid/terpene summaries, and nutrient cost per pound.

- Incident/deficiency log with CAPA trail and verification.

Decision matrix: choose and tune your program

| Constraint | Program bias | Why |

|---|---|---|

| High alkalinity/hardness | RO + re-mineralize | Stabilizes pH and reduces precipitation/clogs |

| Labor-limited ops; inert media | Two-part mineral + pulse automation | Simple, consistent, fast training |

| Premium flavor story; living soils | Biologically active + low-salt supplementation | Emphasizes soil food web; slower to correct shifts |

| Tight budget; high discipline | Dry salts + dosers | Lowest $/gal; demands calibration rigor |

| Water-scarce region; hydro recirc | Closed-loop + sanitation | Cuts usage; requires strong pathogen control |

Next steps and curated inventory

- Calibrate your inputs: Run a fresh water panel; lock finished-water alkalinity, EC, and pH targets; align recipes per substrate and cultivar overlays.

- Publish your schedule: Post the phase schedule and pulse windows at the room entrance; train to it; measure drains daily.

- Harden safety: SDS access, PPE, eyewash, spill kits, and secondary containment verified; HazCom training current.

- Decide build vs. buy: If rehab costs exceed value, move to a shell that fits—or acquire capacity.

Disclaimer

This article is for educational purposes only and does not constitute legal, engineering, financial, or tax advice. Always consult qualified professionals and your local Authority Having Jurisdiction before making decisions.

Please visit:

Our Sponsor