Executive Summary (TL;DR)

- Hydrocarbon extraction (butane/propane blends) is the dominant method for premium concentrates because it preserves terpenes and yields diverse textures (shatter, badder, live resin).

- Success hinges on real estate and code: a compliant C1D1 or C1D2 room, correctly permitted equipment, gas detection, ventilation, and hazardous material controls.

- Landlords and operators must plan tenant improvements (TI), life-safety interlocks, and acceptance testing with the fire marshal and other Authorities Having Jurisdiction (AHJs).

- Deal teams should model TI budgets, throughput, and lease structure, then monitor DSCR and uptime as key drivers of value.

- If you need a turnkey site or are ready to scale, explore manufacturing and processing opportunities on 420 Property’s marketplace.

Start here: browse active manufacturing/processing businesses for sale to benchmark layouts, equipment packages, and pricing:

Cannabis manufacturing & processing businesses

Table of Contents

- Hydrocarbon Extraction: What It Is and Why It Wins Premium SKUs

- Regulatory Framework & AHJs (fire/building, environmental, licensing)

- Hydrocarbon Extraction Process 101 (from biomass to finished goods)

- Facility Design: C1D1 vs. C1D2, ventilation, sensors, and MAQs

- Real Estate & Zoning: buffers, CUPs, LUCS, EFU/Goal 3, and local nuance

- Water, Waste, and Environmental: stormwater, hazardous waste, air permits

- Deal Structure & Financing: TI, capex, lease terms, and DSCR considerations

- Due Diligence & Timelines: sequencing plans, peer review, and acceptance tests

- Buyer & Landlord Checklists

- FAQs

- Call to Action

Hydrocarbon Extraction: What It Is and Why It Wins Premium SKUs

Hydrocarbon extraction uses light hydrocarbons—primarily n-butane, isobutane, propane, or blends—as solvents to selectively dissolve cannabinoids and terpenes from cannabis or hemp biomass. Compared with ethanol or supercritical CO₂, hydrocarbons operate at relatively low pressures and temperatures, helping preserve monoterpenes and produce high-end concentrates (live resin, sauce, badder) with strong flavor retention.

From an M&A and site-selection standpoint, hydrocarbon extraction is attractive because:

- It can deliver competitive yields per pound with short cycle times.

- It supports a wide menu of SKUs—crumble, shatter, live batter, HTFSE/HTFSE-THCa—addressing shifting wholesale trends.

- It scales from boutique to industrial, provided the facility meets Class I, Division 1 (C1D1) or Class I, Division 2 (C1D2) hazardous location requirements and Maximum Allowable Quantities (MAQs) for flammable gases/liquids are respected.

For buyers, landlords, and brokers, the trade-off is straightforward: premium outputs in exchange for the most stringent code, safety, and permitting requirements in cannabis manufacturing.

Regulatory Framework & AHJs (Fire/Building, Environmental, Licensing)

Hydrocarbon rooms sit at the intersection of several code families and regulators—each can impact schedule and cost:

- Fire & Building Codes: International Fire Code (IFC) chapter on processing and extraction; NFPA standards for flammable gases and liquids; electrical classification (C1D1/C1D2); ventilation and LEL (Lower Explosive Limit) detection; e-stop; emergency power for safety systems; and MAQ control areas.

- Equipment Compliance: Listed/approved extraction skids (e.g., UL/OOI such as UL 1389 Plant Oil Extraction Equipment), pressure vessels in accordance with ASME standards, and engineered relief (PSV/PRV).

- Environmental & Health: Air permits for VOCs, solvent loss controls and condensers, hazardous waste management for spent media/solvents, wastewater pre-treatment, and odor mitigation.

- Cannabis Licensing: State cannabis agencies (e.g., DCC, MCA, CRC, OCM) and local business licenses. Where applicable, seed-to-sale (e.g., METRC) ties production batches to inventory controls and SOPs.

- Local Authorities Having Jurisdiction (AHJs): Fire marshal, building department, planning/zoning, and health department—each may require submittals, inspections, and sign-offs.

Key takeaway: plan for multiple review cycles. Many jurisdictions require a third-party engineering peer review, detailed SOPs, a hazardous materials inventory statement (HMIS), and acceptance testing with smoke/LEL simulation.

- Material preparation

- Fresh frozen or dried biomass is staged; moisture and terpene targets drive method (live vs. cured).

- Pre-chilling columns and solvent reduces waxes/lipids pickup.

- Solvent dissolution

- Butane/propane flows through a closed-loop extractor (material column → collection).

- Temperature/pressure controls improve selectivity and cycle time.

- Solvent recovery

- Heat exchangers and recovery pumps vaporize and recapture solvent to a storage tank.

- Condensers and chillers minimize vented losses and VOC emissions.

- Post-processing

- Winterization (if needed), filtration, and decarboxylation for certain derivatives.

- Controlled purge under vacuum ovens to meet residual solvent limits.

- Crystallization or “jar tek” for high-terpene full spectrum extracts (HTFSE) and THCa isolate.

- Packaging & QA

- Batch records, COAs, potency, residual solvents, microbials, and homogeneity tests.

- METRC or state tracking reconciles inputs/outputs for compliance and audits.

Throughput levers: column size and number, heat-exchange capacity, solvent recovery rate, uptime, changeover time, and operator SOP discipline.

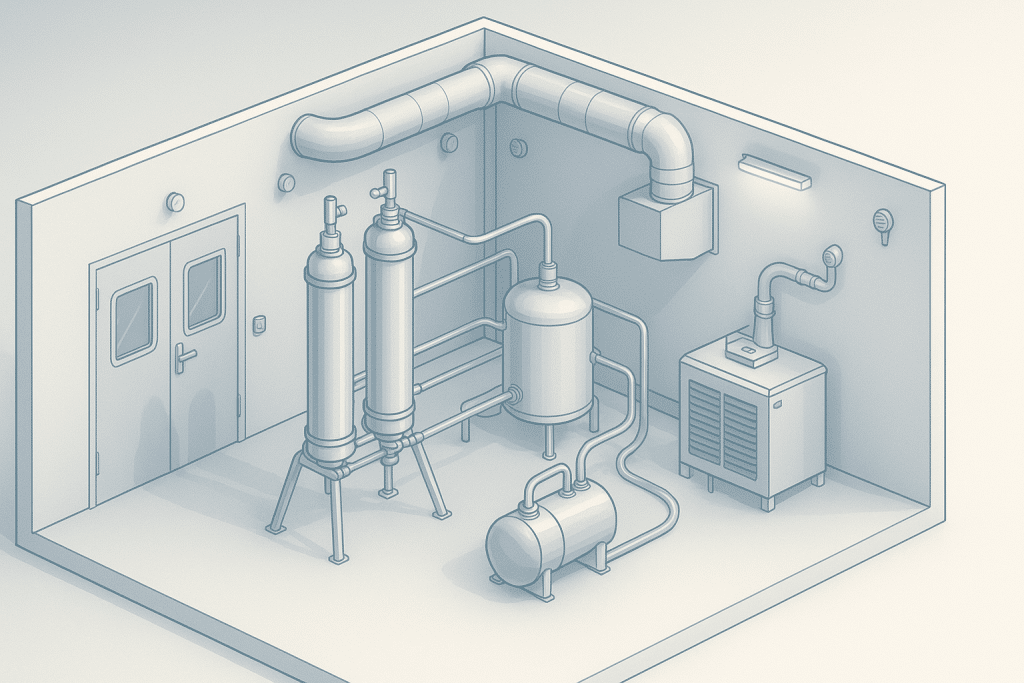

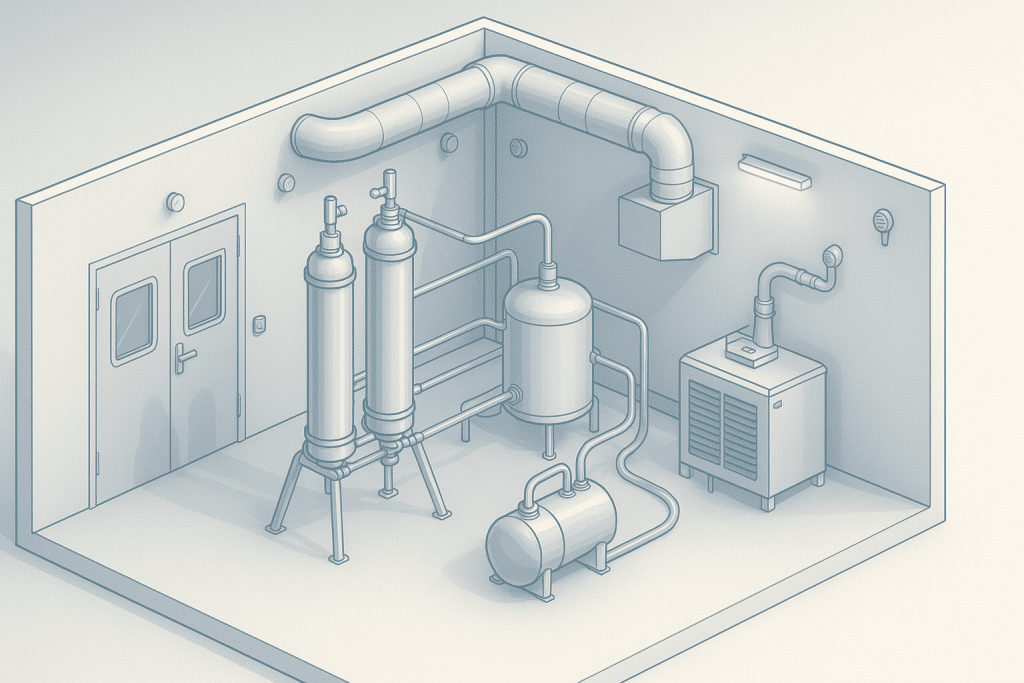

Facility Design: C1D1 vs. C1D2, Ventilation, Sensors, and MAQs

Hazardous location basics

- C1D1 (Class I, Division 1): ignitable concentrations are likely during normal operations—typical for hydrocarbon extraction rooms.

- C1D2 (Class I, Division 2): ignitable concentrations not likely in normal operation—often used for ancillary or adjacent spaces (e.g., vacuum oven rooms if risk is controlled).

Core design elements

- Ventilation & Purge: Continuous exhaust with air changes sized by hazard analysis; makeup air with pressure cascades to keep vapors inside the room; ducting routed to safe discharge points.

- Gas Detection & Interlocks: Fixed LEL sensors with alarm setpoints and hard-wired interlocks to cut non-classified power, trigger ventilation high speed, and latch emergency stop (E-stop).

- Electrical: Classified fixtures and wiring methods; intrinsically safe barriers for sensors inside the classified envelope.

- Fire Protection: Sprinklers per occupancy/hazard classification; fire-rated walls/doors, and deflagration control where required by engineering analysis.

- Solvent Storage & MAQs: Control areas with Maximum Allowable Quantities; flammable gas cylinders in ventilated cabinets or exterior cages; grounding/bonding; documented cylinder changeout SOPs.

- Listed Equipment: Extraction skids, recovery pumps, ovens, and controls should be listed/approved for the application (e.g., UL/ETL to applicable standards), or supported by a field evaluation and peer review.

Acceptance testing

Expect functional tests for LEL alarms, interlocks, e-stop, ventilation fail-safes, emergency lighting, and signage, witnessed by the fire department and building officials.

Real Estate & Zoning: Buffers, CUPs, LUCS, EFU/Goal 3, and Local Nuance

Extraction is not just about the room—it’s about the address:

- Zoning & Buffers: Many municipalities require buffers from sensitive uses (schools, parks) and limit cannabis manufacturing to industrial districts. Early verification with planning staff prevents dead-end deals.

- CUP & LUCS: A Conditional Use Permit (CUP) or a Land Use Compatibility Statement (LUCS) (where applicable) may be required to confirm cannabis manufacturing is allowed on the parcel.

- EFU & Goal 3 (Agriculture): In Oregon contexts, Exclusive Farm Use (EFU) zones and Goal 3 agricultural protections can shape feasibility for greenhouses and processing ancillaries.

- Parking & Loading: Delivery/wholesale operations need secure loading, camera coverage, and sight lines that meet local cannabis ordinances.

- Power & Utilities: Three-phase power for chillers and HVAC, adequate water and drainage, and roof/structural capacity for makeup air and exhaust penetrations.

Pro tip for brokers and landlords: when marketing an asset, publish utility specs (kVA, panel sizes), ceiling heights, and any prior CUP/LUCS approvals. It shortens diligence and supports higher offers.

Water, Waste, and Environmental: Stormwater, Hazardous Waste, Air Permits

- Stormwater & SPCC: Exterior cylinder storage or condenser units may trigger stormwater best practices; secondary containment and roof drainage control help.

- Hazardous Waste: Spent solvent, contaminated wipes/media, and lab chemicals may fall under hazardous waste rules—segregate streams, label properly, and contract licensed haulers.

- Air Permits & Odor: VOCs from solvent losses can trigger local air quality reviews; odor mitigation (carbon, thermal oxidation) may be required by ordinance.

- Wastewater: Pre-treatment for distillation bottoms and cleaning solutions; never discharge hydrocarbons to sanitary or storm systems.

- Wetlands & Riparian Setbacks: For campuses or greenhouses on rural parcels, confirm wetlands delineation, riparian setbacks, and floodplain constraints early.

Deal Structure & Financing: TI, Capex, Lease Terms, and DSCR

Hydrocarbon labs have some of the highest tenant improvement (TI) line items in cannabis because life-safety systems must be engineered, installed, and commissioned to code. In underwriting:

- Capex & TI: Extraction skid, chillers, compressed air, ovens, ventilation, gas detection, classified electrical, peer review, and acceptance testing.

- Lease Structures:

- NNN: Tenant pays taxes/insurance/maintenance—common for industrial; clarify responsibility for classified electrical, ventilation fans, roof penetrations, and end-of-term restoration.

- Full Service Gross: Simpler monthly but landlords should price in higher utilities and filter changes for continuous ventilation.

- ROFR/Assignments: Useful when consolidators expand; ensure assignment rights consider cannabis licensing approvals.

- Financial Metrics: Underwrite to conservative throughput and yields, adjust for downtime and learning curves, and track Debt Service Coverage Ratio (DSCR) to satisfy lenders or sale-leaseback investors.

Due Diligence & Timelines: Sequencing Plans, Peer Review, and Acceptance Tests

A practical path from LOI to first production:

- Feasibility & Schematic Design

- Zoning, buffers, and CUP/LUCS checks; utility survey; code review for C1D1/C1D2; preliminary HMIS and MAQs by control area.

- Engage licensed fire protection/mechanical/electrical engineers.

- Peer Review & Submittals

- Third-party engineering peer review of process, controls, and room classification.

- Submit drawings, calculations, and equipment cut sheets. Include SOPs (start-up, shutdown, emergency, cylinder handling).

- Permit Review Cycles

- AHJ comments → design revisions; schedule long-lead equipment; order listed skids early to avoid commissioning delays.

- Buildout & Pre-Functional Testing

- Install ventilation, gas detection, electrical classification, and controls; verify interlocks; pre-commission extractor with nitrogen.

- Acceptance Testing & Occupancy

- Conduct witnessed tests (LEL alarms, e-stop, airflow, emergency power), deliver as-builts and O&M manuals, then pursue certificate of occupancy and cannabis license amendments.

Common bottlenecks: late equipment listing documentation, unclear MAQ accounting, and missing interlock logic diagrams.

Buyer & Landlord Checklists

Buyer / Operator

- Confirm zoning and required CUP/LUCS approvals.

- Request equipment lists with standard listings (e.g., UL/ETL) and ASME vessel certifications.

- Review ventilation design, LEL sensor coverage, and e-stop plan.

- Validate MAQs and control areas; inspect solvent storage and cylinder logistics.

- Evaluate SOPs (start-up/shutdown/emergency), training, and lockout/tagout.

- Scrub batch records, METRC compliance, QA/COAs, and residual solvent data.

- Underwrite utilities (kWh/tonnage) and uptime; build a spare-parts inventory plan.

Landlord / Broker

- Publish utility specs (amps/kVA), clear heights, loading, and any prior cannabis entitlements.

- Clarify lease responsibilities for classified electrical, roof penetrations, and ventilation maintenance.

- Require restoration and decommissioning protocols (e.g., solvent lines purge, cap, and tag).

- Confirm insurance requirements (GL, property, products, pollution riders as required by lender).

- For marketing, organize a data room: drawings, peer review letter, acceptance test summaries, and maintenance logs.

FAQs

Is hydrocarbon extraction safe?

Yes—when engineered and operated correctly. Safety depends on listed equipment, a compliant C1D1/C1D2 environment, gas detection and interlocks, trained staff, and rigorous SOPs.

Can I place hydrocarbon extraction in any industrial building?

Not automatically. You need compatible zoning, buffer compliance, sufficient utilities, structural allowances for ventilation, and a willing landlord. Many jurisdictions require CUP or LUCS-style compatibility confirmations.

What drives lab throughput the most?

Column capacity, recovery heat-exchange, solvent chilling, changeover time, and operator discipline. Process bottlenecks often live in recovery and post-processing (ovens/crystallization).

How does hydrocarbon compare to ethanol or CO₂?

Hydrocarbons excel at terpene retention and premium textures; ethanol favors high-throughput crude; CO₂ appeals for tunability and reduced flammability. Your go-to method should match target SKUs and regulatory comfort.

What inspections should I expect?

Plan check reviews, on-site fire/building inspections, extraction acceptance testing (LEL/e-stop), and cannabis licensing inspections. Some AHJs require annual life-safety re-inspection.

Call to Action

If you’re evaluating a hydrocarbon lab—whether to launch, scale, or acquire—make your next move on 420 Property:

This article is for educational purposes only and does not constitute legal, engineering, financial, or tax advice. Always consult qualified professionals and your local Authority Having Jurisdiction before making decisions.

Please visit:

Our Sponsor