Executive Summary (TL;DR)

- Inspectors focus on three pillars: odor mitigation, waste management, and fire/life safety. Show your plan, prove it works, and document it.

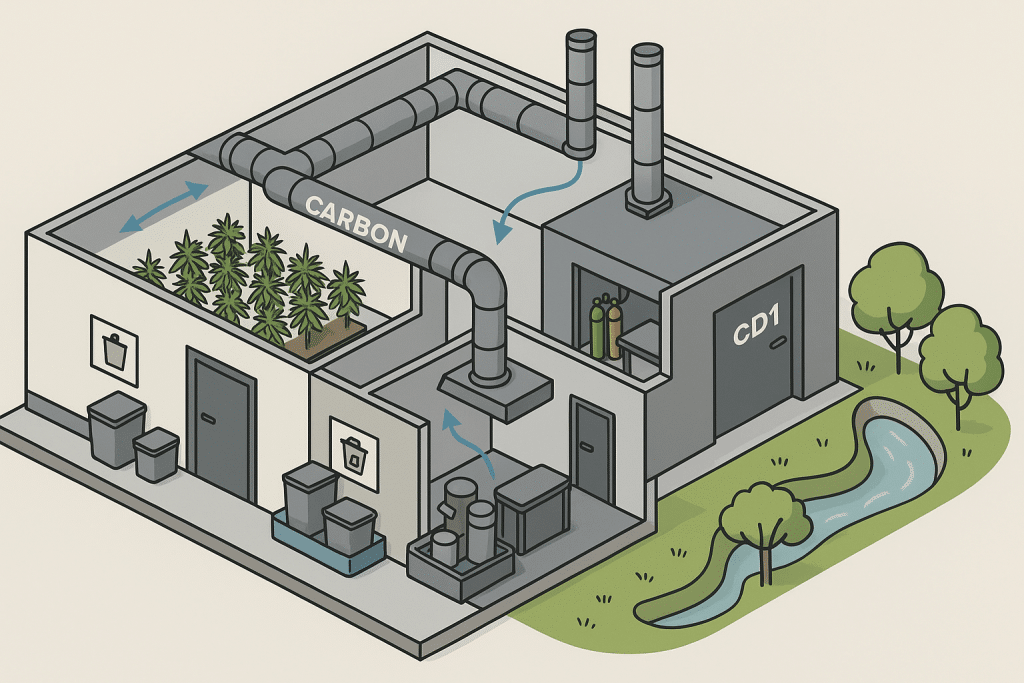

- For odor mitigation, design to measurable outcomes (containment, capture, treatment) using negative pressure, filtration, and verifiable maintenance logs. This is the heart of cannabis odor mitigation compliance.

- Waste programs must track plant, solvent, and universal waste from generation to final disposition with chain-of-custody records that match METRC/seed-to-sale where applicable.

- Fire code reviews are stringent for extraction: electrical classification (e.g., C1D1), ventilation, monitoring, and maximum allowable quantities (MAQs) are non-negotiable.

- Landlords and buyers should underwrite TI budgets, timeline risk, and DSCR impact of compliance upgrades; align leases so responsibilities are clear.

Ready to position your facility for inspections and lease-up? Browse compliant properties for lease on 420 Property:

Search cannabis real estate for lease

Table of Contents

- Why odor, waste, and fire code drive approvals

- Inspector expectations for odor mitigation

- Waste controls (plant, solvent, universal, stormwater)

- Fire and life safety (extraction, storage, alarms)

- Land use, zoning, and site prerequisites

- Landlord/Investor underwriting: TI, DSCR, and timeline risk

- Documentation package: what to hand an inspector

- Buyer/Seller checklists for diligence and M&A

- FAQs

- Call to action

Why These Three Areas Drive Approvals

Local Authorities Having Jurisdiction (AHJs) and state cannabis agencies evaluate risk through a practical lens: nuisance control (odor), environmental/public health (waste), and life safety (fire code). If you can’t show a coherent plan—grounded in code, equipment specs, and maintenance—your opening date slips, tenant improvements (TI) grow costlier, and financing covenants (e.g., Debt Service Coverage Ratio (DSCR)) get strained.

These factors also influence property value and deal certainty in leases, purchases, and business sales. A site that demonstrates proven cannabis odor mitigation, audited waste logs, and code-conforming extraction will appraise better and close faster, whether you’re leasing a build-to-suit or signing an APA/stock purchase.

Inspector Expectations for Odor Mitigation

What “good” looks like

Inspectors typically expect you to demonstrate:

- Containment — Keep odors in the source room via room integrity, closed doors, and pressure cascades (e.g., grow rooms slightly negative to adjacent corridors).

- Capture — Pull air through hoods, canopy-level intakes, or duct drops sized for canopy density and transpiration rates.

- Treatment — Filter or scrub the air before discharge, with verifiable maintenance (media change-out logs).

A credible cannabis odor mitigation plan combines:

- Pressure strategy (negative relative to adjacent spaces; vestibules at entries).

- Filtration (deep-bed activated carbon canisters with contact time sized to cfm; MERV 13–15 prefilters to protect carbon).

- Air changes tailored to room function (veg/flower/dry/cure) and heat/moisture loads.

- Sealed paths (proper ductwork, tight penetrations, gasketed doors) to avoid bypass.

- Commissioning data (differential pressure readings, cfm per room, and odor surveys at property line).

Myth vs. Fact

Myth: A couple of inline fans with small carbon filters will satisfy inspectors.

Fact: Most AHJs want a stamped mechanical design that shows pressure, cfm, filter bed depth/contact time, and access for service—plus a PM (preventive maintenance) schedule.

Where odor intersects zoning and entitlements

- Zoning & CUP: Many jurisdictions require a Conditional Use Permit (CUP) that conditions operation on zero-detectable odor at the property line. Your cannabis odor mitigation plan must align with the CUP narrative.

- Buffers & overlays: Sensitive-use buffers (schools, daycares, parks) may necessitate odor assurances during hearings.

- Oregon-specific references: Where applicable, municipalities may require a Land Use Compatibility Statement (LUCS) for land use verification; agricultural zones like Exclusive Farm Use (EFU) and Goal 3 (Agriculture) can shape greenhouse retrofits.

Waste Controls (Plant, Solvent, Universal, Stormwater)

A compliant waste program is built on classification, containment, labeling, storage time limits, and disposal documentation:

1) Plant waste

- Segregation: Keep plant material separate from other wastes; maintain seed-to-sale reconciliation.

- Rendering unusable: Many jurisdictions require rendering (e.g., mixing with non-consumables) before off-site transport. Confirm local thresholds rather than assuming a fixed ratio.

- Records: Dated photos, weight logs, and manifests should match inventory system outputs.

2) Process solvents and residuals

- Ignitables (e.g., ethanol) and flammable gases (butane/propane) are managed under fire code and hazardous waste rules where applicable.

- Container specs: Closed, compatible containers with secondary containment and spill kits; post Safety Data Sheets (SDS) at points of use.

- Accumulation limits: Follow maximum allowable quantities (MAQs) and storage time limits; label containers with full chemical names.

3) Universal and e-waste

- Lamps, batteries, electronics (grow lights, backup batteries, sensors) typically follow universal waste rules with labeling and dated accumulation.

- Vendor take-back can streamline compliance.

4) Stormwater and wastewater

- Stormwater: Outdoor storage, vehicle staging, and loading areas can trigger stormwater management and best management practices (BMPs).

- Wastewater: Trimming/drying rooms may discharge high-organics wastewater; consult your sewer authority.

- Wetlands & riparian corridors: On greenfield or rural sites, confirm wetlands delineation and riparian setbacks to avoid enforcement.

Decision Matrix: Who owns the waste program?

| Scenario | Landlord Role | Tenant Role | Lease Clause to Add |

|---|---|---|---|

| Single-tenant NNN, tenant runs extraction | Provide base-building containment & spill control | Create SOPs, train staff, maintain logs | Hazardous waste indemnity; reporting cadence |

| Multi-tenant industrial w/ shared yard | Keep stormwater BMPs, maintain site plan | Segregate waste, label, store in suite | Shared-cost OPEX pass-through for BMPs |

| Greenhouse w/ composting plan | Approve compost vendor/site | Operate composting per local rules | Site plan approval + inspection rights |

Fire and Life Safety (Extraction, Storage, Alarms)

Core elements inspectors verify

- Process classification: Hydrocarbon extraction requires Class I, Division 1 (C1D1) enclosures with interlocked ventilation and gas detection. Ethanol systems may be C1D2 depending on design.

- MAQs & control areas: Document total volumes of flammables and compressed gases relative to control areas and construction type.

- Engineering controls: Explosion-proof components where required, intrinsically safe wiring, emergency power for exhaust/gas detection, and interlocks to shut down ignition sources.

- Ventilation: Capture velocities at hoods/booths, continuous monitoring, and alarm annunciation.

- Detection & suppression: Fire alarm with manual pull stations as required; sprinklers per hazard classification; portable extinguishers with correct ratings.

- Pre-functional tests: Factory acceptance tests (FAT) for equipment, then site acceptance tests (SAT) witnessed by the AHJ.

Common gap: Substituting “lab-style” gear for code-listed extraction equipment. Inspectors typically ask for listing documentation, peer review (where adopted), and stamped MEP drawings.

Land Use, Zoning, and Site Prerequisites (Don’t Skip)

Even if your immediate focus is cannabis odor mitigation or fire code, projects stall without land-use alignment:

- Zoning & LUCS/CUP: Confirm zoning, obtain LUCS (in Oregon) or equivalent local verification, and secure a CUP where required.

- Buffers: Map sensitive uses and setbacks early; some communities add overlay zones with special odor or traffic conditions.

- Parking & circulation: Delivery and waste removal routes influence odor and fire department access.

- Power & utilities: Extraction/HVAC upgrades often require new service; sizing late can blow TI budgets and delays.

Landlord/Investor Underwriting: TI, DSCR, and Timeline Risk

TI and base-building scope

- HVAC & filtration: Larger AHU/MAU units, deep-bed carbon, energy recovery, and upgraded duct/hood systems.

- Electrical: Classified wiring (C1D1/C1D2), emergency power, panel capacity, and fault current studies.

- Fire protection: New sprinklers/densities, wet chemical systems for kitchens, and alarm integration.

- Envelope & site: Vestibules, door hardware, sealed penetrations, odor stack locations, and roof pathways.

Lease mechanics that reduce risk

- Work letter clarity: Separate base-building (landlord) vs. process equipment (tenant).

- Milestone-based rent: Tie rent commencement to receive TCO/CO and fire final; protects DSCR if approvals slip.

- Compliance riders: Require maintaining the cannabis odor mitigation program, filter change logs, and rapid corrective actions for complaints.

- Insurance/indemnities: Align coverage to process hazards; require named insured, completed-operations, and pollution riders where relevant.

Documentation Package: What to Hand an Inspector

Create a single, indexed binder (digital + hardcopy):

- Code path memo: Applicable building code, fire code edition, and local amendments.

- Stamped drawings: Mechanical, electrical, plumbing, structural (if needed), and life-safety plans.

- Odor plan: Narrative, room pressure schedule, filtration specs, locations, change-out schedule, and commissioning data.

- SOPs: Waste handling (plant/solvent/universal), spill, leak detection, hot-work, lockout/tagout.

- Equipment files: Cut sheets, listing marks, gas detection calibration procedures, and maintenance PMs.

- Training logs: Names, dates, and curricula for waste, fire extinguisher, evacuation.

- Vendor agreements: Waste haulers, hood cleaning, filter replacement, alarm monitoring.

- Incident procedures: Emergency contacts, authority notification flow, after-action reporting template.

Buyer/Seller Checklists (Diligence & M&A)

For Buyers (operators, investors, brokers)

- Odor: Has the facility passed a recent inspection? Get pressure logs, filter invoices, and any complaint records.

- Waste: Request manifests, METRC reconciliations, and solvent inventory logs.

- Fire: Verify C1D1 listings, MAQ calculations, pre-functional test reports, and fire marshal sign-offs.

- Zoning: Confirm CUP conditions and expiration/renewal terms; check stormwater permits on industrial yards.

- Capex: Independent estimate of remaining TI for compliance; model rent commencement and DSCR sensitivity.

- Land/water: On rural/greenhouse assets, confirm any wetlands delineation or riparian setbacks that constrain expansion.

For Sellers (landlords, operators)

- Organize the binder above; preempt surprises.

- Resolve small items before listing (e.g., expired extinguisher tags, missing SDS sheets).

- Disclose capacity limits honestly (e.g., MAQs, fan cfm).

- Provide service contracts that can be assigned at closing.

- Highlight wins (complaint-free record, recent filter upgrades, passed performance tests).

Looking for assets that already solved odor and fire code? See cannabis businesses for sale with operational histories:

Explore active cannabis businesses

FAQs

Q1: Do all cultivations need negative pressure?

Not always, but most odor conditions and CUPs expect containment. Negative pressure with defined pressure cascades remains a reliable strategy for compliance.

Q2: Is rendering plant waste with non-consumables required everywhere?

No. Requirements vary by state and municipality. Some require rendering unusable; others allow direct disposal with chain-of-custody. Confirm with your AHJ.

Q3: When is C1D1 mandatory?

Where flammable gases (e.g., hydrocarbon extraction) or certain vapor hazards are present. Many ethanol systems are engineered as C1D2 or inside listed equipment—your process hazard analysis and code path dictate the classification.

Q4: Can a robust odor plan reduce neighborhood opposition?

Yes. A stamped plan with measurable outcomes (property-line odor targets, change-out frequencies) often eases CUP hearings and operational complaints.

Q5: Who pays for compliance upgrades—landlord or tenant?

It depends on the work letter. Base-building items (e.g., sprinkler main, structural supports for roof equipment) are often landlord scope; process gear (extraction) is tenant. Spell it out and align rent commencement.

Call to Action

Solve compliance first, then scale operations with confidence. Whether you’re upgrading a current site or sourcing a new address:

This article is for educational purposes only and does not constitute legal, engineering, financial, or tax advice. Always consult qualified professionals and your local Authority Having Jurisdiction before making decisions.

Please visit:

Our Sponsor